Past Projects

- AWE

- BIOBACTIL

- DNASiP

- Films Multifonctionnels

- Food Screening EMR

- GREEN+

- HM+

- Intense4Chem

- MAPIU

- MAVERIC

- MEDIATIC

- MICROLUB

- Micro+

- MINATIS

- MINT

- MONA

- OPTIGRID

- PIμI

- ROMISY

- SANE

- SWS

- TOPPRINT

- TRUSTEYE

- WEARIT4HEALTH

AWE (2015 – 2016)

Within the framework of the AWE project, Microsys has developed a shoe able to harvest energy from walking in order to power a microsystem. The harvesting system, based on Microsys EP11186268 patent, produces enough energy to measure 1-axis acceleration at 30 Hz and to send the data wirelessly to a remote data concentrator station. Both the energy harvesting system and the microsystem have been integrated in the shoe’s sole. Potential applications are sport performance analysis, gait analysis, activity monitoring etc.

Ref:

G. Colson, P. Laurent, P. Bellier, S. Stoukatch, F. Dupont, M. Kraft, "Smart-shoes self-powered by walking", Proc. IEEE EMBS Body Sensor Network 2017, Eindhoven, The Netherlands, 9-12 May 2017.

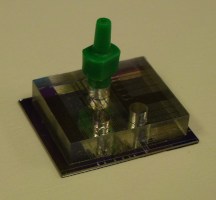

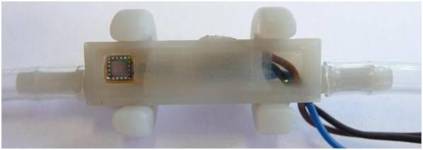

BIOBACTIL (2014-2017)

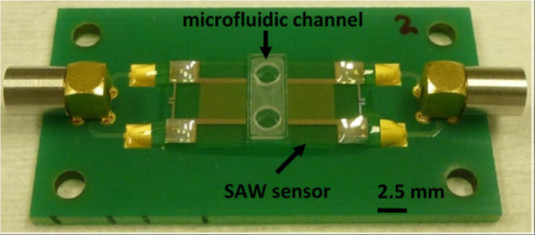

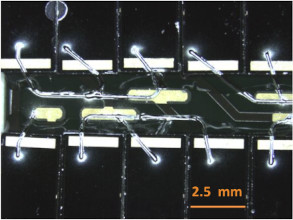

BIOBACTIL project target the direct detection of bacteria in a lab-on-chip opto-fluidic platform compliant with a panel of immunological transducers. Microsys task in the project is the integration of the sensor into the lab-on-chip platform: die attach, wirebonding, encapsulation, microfluidic channel integration and test. The main challenge of the project was to ensure that the implemented packaging has no significant impact on the functionality of the SAW sensor. Furthermore, only low-temperature packaging methods were used, to ensure compatibility with biofunctionalized sensors.

Ref:

S. Stoukatch, L.A. Francis, F. Dupont, M. Kraft, "Low-cost microfluidic device micromachining and sequential integration with SAW sensor intended for biomedical applications", Sensors and Actuators A: Physical, Volume 319, 2021.

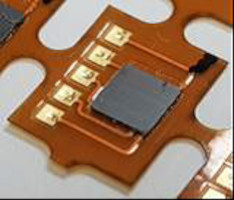

DNASiP (2010 – 2012)

The objective of DNASiP project was the development of DNA functionalized microchip integrated in microfluidic SiP (System-in-Package). Microsys main task in the project was the integration of the interdigitated capacitive sensor, taking into account the constraints related to the use of biofunctionalized chips. Low temperature packaging methods have been developed and implemented.

Ref:

S. van Loo, S. Stoukatch, N. Van Overstraeten-Schlögel, O. Lefèvre, F. Axisa, D. Flandre and J. Destiné, "Low temperature assembly method of microfluidic bio-molecules detection system", 3rd IEEE International Workshop on Low Temperature Bonding for 3D Integration (LTB-3D 2012), Hongo, Japan, May 22-23, 2012.

Films Multifonctionnels (ERDF program 2014 - 2020)

Films Multifonctionnels is a huge projects portfolio that pools state-of-the-art scientific expertise and equipment in the field of coatings. Within the portfolio, Locoted projects aim to develop new efficient and low-cost thermoelectric films, to be implemented in thermoelectric generators for both heat waste recovery in industry and autonomous sensors nodes power supply. Microsys is in charge of developing a prototype of autonomous microsystem that harvests its energy through these new materials. The prototype will integrate into one miniaturized device the thermoelectric film, the sensors and the electronic system.

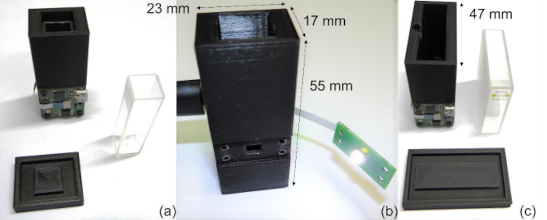

Food Screening EMR (Interreg EMR, 2021 – 2023)

The project Food Safety EMR aims at supporting local SMEs in the transition to the future-proof farming industry. The aim of the project is to provide these enterprises with the newest insights into best practices and technological advances by adapting a co-creation process between euregional farmers and food producers on the one hand and technological SMEs in the region and the key euregional universities on the other hand. The Sensor Engineering Department of UM will collaborate with IMO-IMOMEC to develop these receptors, couple them to suitable dyes and integrate the dye-loaded vitamin receptors into a lab-on-a-chip or lab-on-a-card technology. This will enable end-users to liquify their products and analyze their vitamin content using a simple dipstick. Binding of vitamins to the receptors in the dipstick will lead to displacement of the dye to a detector pad in the dipstick displaying a color reaction. The more intense the coloring in this zone, the more vitamin C was present in the original sample under study. To quantify this reaction on-site and to turn the color signal into a concentration reading, UM and IMO-IMOMEC will team up with the engineering departments of RWTH Aachen and ULiège (Microsys). The consortium aims to develop a handheld readout tool that enables the end-user to plug in the dipstick loaded with the food sample and interpret the result on-site on a display or a laptop onto which the readout device can be plugged in.

Ref:

www.youtube.com/watch?v=heIqOXTIT1M

F. Dupont, S. Stoukatch, P. Laurent, K. Eersels, B. van Grinsven, J.-M. Redouté, "Design Aspects for Portable LED-Based Colorimetric Characterisation Systems Targeting Liquid Analytes", Sensors 2024, vol. 24, 1960.

S. Stoukatch, F. Dupont, J. W. Lowdon, G. van Wissen, K. Eersels, B. van Grinsven, and J.-M. Redouté, "Novel low-cost instrumentation based on an RGB-sensor using molecularly imprinted polymers (MIPs) for the rapid detection of aqueous 2-methoxphenidine (2-MXP)", Journal of Sensors and Sensor Systems, Accepted for publication.

GREEN+ (2009 – 2013)

The objective of GREEN+ project was to develop a compact and decentralized double flow ventilation system including an exhaust air energy recovery system. The system is adaptable to both existing and new buildings. Within the project, Microsys was in charge of the prototyping of the miniaturized electronic circuit, the integration of the sensors and the development of the control and regulation system. The system is currently commercialized under the brand Airria (www.airria.be).

HM+ (2008 – 2012)

HM+ was a large-scale project targeting the development of predictive maintenance systems dedicated to aeronautic applications. Three subsystems of aircrafts were selected for health monitoring systems implementation: the electrical distribution network, the engine and lubrication system, and the moving parts.

Microsys was involved in the development of a monitoring system whose purpose is to detect misalignments of the slats during their actuation. Microsys was also involved in the integration of new type of oil ageing monitoring system based on quartz microbalance sensors.

Ref:

Didier Deplaen, Bruno Heusdens, Francois Dupont, Michel Saint-Mard. "Désalignement de surfaces portantes", EP2392510 (A1), 2011-12-07.

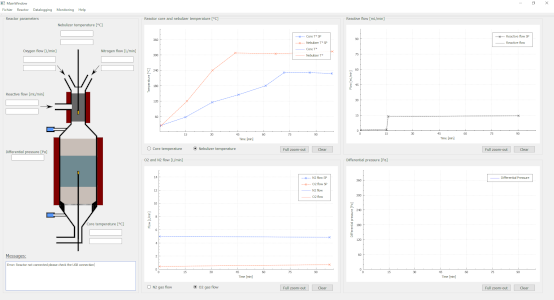

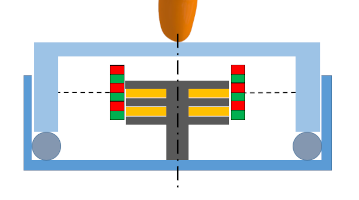

Intense4Chem (ERDF program 2014 - 2020)

Intense4Chem project portfolio targets the development of intensified, low-cost, fast, efficient and with a reduced environmental impact processes in order to produce key molecules for the chemical industry. In particular, Flow4Reactors projects, in which Microsys is taking part, aims at intensifying chemical processes by means of catalytic structured microreactors. Microsys is in charge of developing a fully integrated sensing and regulation system that will eventually be integrated to the microreactor prototype. This task includes both the hardware design of the regulation platform and the implementation of the user interface.

MAPIU (2018 – 2020)

MAPIU project aims to develop a wireless, miniaturized multi-sensor monitoring system powered by energy harvesting. This system includes several sensors (temperature, humidity etc.) and is used to ensure monitoring and traceability of goods during transport. The generated data is processed via the Cloud and made available to the end user via a responsive interface. Microsys task in the project was to develop the energy harvesting unit as well as the development of the ultra-low-power wireless sensor node compatible with the base station of projects partners.

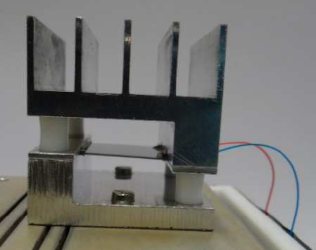

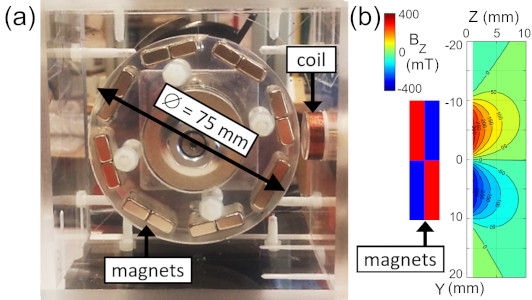

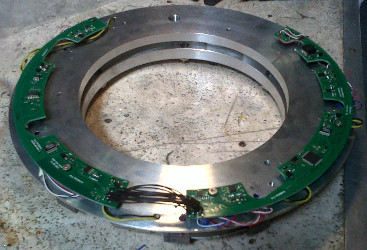

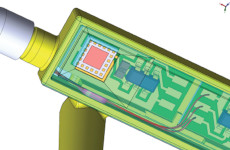

MAVERIC (2017 – 2021)

The objective of the MAVERIC project is to develop passive and hybrid (passive/active) adaptive vibration absorber with application mainly in aeronautics. Within the framework of the project, Microsys objective is implementing energy harvesting methods in order to ensure the energy autonomy of the absorber. Indeed, in the main application case targeted by the project (aircraft engine components), a wired power supply is not possible due to rotating parts. An optimized electromagnetic harvester, including the electronic power management unit, is being developed and tested.

Ref:

P. Laurent, J.-F. Fagnard, F. Dupont and J.-M. Redouté, "Optimization of the Power Flow Generated by an AC Energy Harvester for Variable Operating Conditions", in IEEE Transactions on Circuits and Systems I: Regular Papers, vol. 69, no. 6, pp. 2625-2636, June 2022, doi: 10.1109/TCSI.2022.3156691.

MEDIATIC (ERDF program 2007-2013)

Within the MEDIATIC portfolio, the Tracemedia project aimed at the development of a high-performance and multimodal platform for receiving data from sensor networks, while providing the middleware application layer for data pre-processing, fusion, classification, and extraction. Microsys task in this project was to develop ultra-low-power sensor nodes for track and trace applications (including environmental parameters monitoring).

Ref:

P. Laurent, F. Dupont, S. Stoukatch, F. Axisa, "Ultra-low power microsystems integrated", Proc. Smart Systems Integration Conf. (SSI2015), Copenhagen, Denmark, March 11-12, 2015.

MICROLUB (2009 – 2011)

MICROLUB project was aiming to develop an innovative technique for micro-lubrication of cutting tools for various manufacturing machines, with the objective to reduce significantly the oil consumption as well as to enable the use of alternative lubricants (e.g. biodegradable). Microsys task in the project was to develop the electronic board for the control and regulation of the lubrication system.

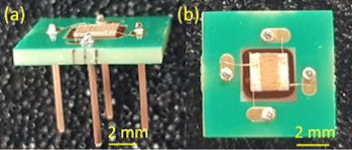

Micro+ (ERDF program 2014 - 2020)

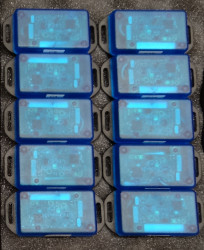

The research in Micro+ is structured around three main objectives related to miniaturized sensor systems. The first is to make microsystems more robust, for applications in harsh environments and in order to increase their lifetime. The second objective is to make microsystems more autonomous. This is done mainly by reducing the power consumption of the sensors and components. Energy harvesting and power management units are also research topics within the project. Finally, the last objective is to extend the wireless capabilities of the microsystems, e.g. increased range or innovative geolocalization features. In addition to these research topics, the project budget also allows for the acquisition of several pieces of equipment: an automatic wirebonder, a high-resolution thermal imaging system, a micro-milling machine etc.

Ref:

S. Stoukatch, J.-F. Fagnard, F. Dupont, P. Laurent, M. Debliquy and J.-M. Redouté, "Low Thermal Conductivity Adhesive as a Key Enabler for Compact, Low-Cost Packaging for Metal-Oxide Gas Sensors", in IEEE Access, vol. 10, pp. 19242-19253, 2022, doi: 10.1109/ACCESS.2022.3151356.

J.-F. Fagnard, S. Stoukatch, P. Laurent, F. Dupont, C. Wolfs, S. Lambert, J.-M. Redouté, "Preparation and Characterization of a Thermal Insulating Carbon Xerogel-Epoxy Composite Adhesive for Electronics Applications", IEEE Transactions on Components, Packaging and Manufacturing Technology, vol. 11, no. 4, pp. 606-615, April 2021.

F. Dupont, S. Stoukatch, P. Laurent, J.-M. Redouté, "Fine Pitch Features Laser Direct Patterning on Flexible Printed Circuit Board", Elsevier Optics and Lasers in Engineering, vol. 126, 2020.

S. Stoukatch, N. André, T. Delhaye, F. Dupont, J.-M. Redouté, D. Flandre, "Anisotropic conductive film & flip-chip bonding for low-cost sensor prototyping on rigid & flex PCB", accepted for presentation at the IEEE Sensors Conference, Rotterdam, The Netherlands, 2020, pp. 1-4, doi: 10.1109/SENSORS47125.2020.9278669.

L. Joris, F. Dupont, P. Laurent, P. Bellier, S. Stoukatch, J.-M. Redouté, "An Autonomous Sigfox Wireless Sensor Node for Environmental Monitoring", IEEE Sensors Letters, 2019.

MINATIS (ERDF program 2007-2013)

MINATIS ERDF portfolio’s objective is to meet the needs of the industry regarding the design and fabrication of miniaturized, multi-functional and embedded devices. Microsys task in the project was the development of new packaging methods for innovative sensors with functionalities and performances beyond the state-of-the-art.

Ref:

S. Stoukatch, L. Seronveaux, P. Laurent, S. Dricot, F. Axisa, D. Vandormael, E.Beeckman, B. Heusdens, J. Destiné, "Evaluation of aerosol jet printing (AJP) technology for electronic packaging and interconnect technique", Proc. The 4th Electronics System Integration Technology Conferences (ESTC 2012), Amsterdam, The Netherlands, Sept 17-20, 2012.

MINT (2008 – 2011)

The aim of MINT project was to develop cheap expert maintenance systems for continuous manufacturing processes. These systems must make maintenance operations more effective by using the opportunities offered by new technologies. In the framework of this project, Microsys was involved in the development of a smart pump for the greasing of bearings. This pump is able to identify the bearing thanks to RFID technology and is able to control and record the amount of grease that has been delivered. The system was eventually licensed to Taipro Engineering.

Ref:

Michel Saint-Mard, Fabrice Haudry, Pierre Bellier, Philippe Laurent, Pascal Waroux, Rachid El Halimi, Eric Darimont. "Dispositif et méthode de contrôle et de validation du graissage manuel", EP12159311.5, 2012-03-13.

MONA (DEFRA, 2021 – 2024)

The MONA project aims to design a Small Energy Harvester System (SEHS), scavenging mechanical energy and converting it into electrical energy in order to power a communication unit or a battery charging device. While most of the mechanical energy harvesters are dedicated to operate at a specific frequency (vibrating mass), the proposed system has the significant advantage to work in an extended frequency range, as well as to be activated by a variety of movements, including a single actuation from a finger or foot depressing a push-button, mechanical vibration during motorized transportation or a sudden shock. The SEHS will consist in a small device (typ. D = 30 mm, H = 10 mm) that can be actuated either from depressing the SEHS (finger/foot/wheel...) or shaking the SEHS (vibration/shocks). Microsys is in charge of the SEHS modeling and implementation, as well as the power management unit design and optimization.

Ref:

Philippe Laurent. "Energy harvesting system using one or more energy sources", EP11186268.6, 2011-10-01.

OPTIGRID (2013 – 2016)

The target of this project was to develop a smart sensor for high and medium voltage lines, with predictive maintenance functionality and fault detection. Microsys task in the project was to assist in the choice of the sensors and to develop the embedded software to communicate and process the data of all the sensors with a real-time operating system.

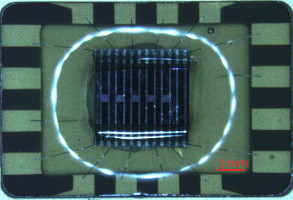

PIμI (ERDF program 2007-2013)

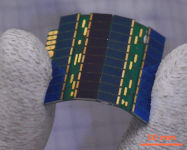

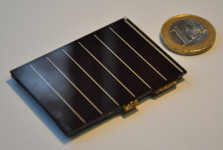

PIμI is a large-scale ERDF portfolio in the field of integrated microelectronic systems. The portfolio is divided into several projects that target respectively (1 – Remanos) the development of self-powered microsystem through energy harvesting, (2 – Monsotex) the integration of sensors in textile for medical application, (3 – Medipump) the integration of electronics into a new generation of smart medical perfusion pump and (4 – Mifadema) the development of a platform for microfabrication by deposition material.

Ref:

S. Stoukatch, J. Léonard, P. Bellier, F. Axisa, J. Destiné, "Wearable respiratory belt for human breathing control", Proc. Smart Systems Integration Conf. (SSI2014), Vienne, Austria, March 11-12, 2014

P. Bellier, P. Laurent, S. Stoukatch, F. Dupont, L. Joris, M. Kraft. "Autonomous micro-platform for multisensors with an advanced power management unit (PMU)", Journal of Sensors and Sensor Systems 7, no. 1 (2018): 299.

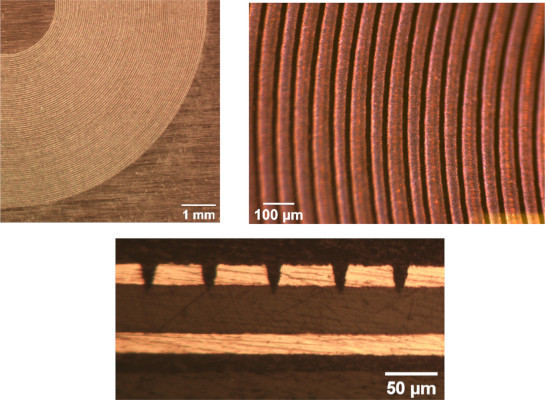

ROMISY (2012 – 2017)

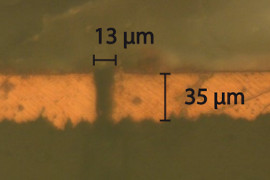

The project aim was to design and test new architectures for microsystems including multi-physics simulation technique, improved processing methodologies and test to meet the growing market demands in terms of reliability and robustness both in front end and back end level. During the project, Microsys provided support for modelling of electronics interconnection so that project partners can develop the toolbox in multi-physics software (FEM simulation) to model wire bond adhesion to the bond pad. In parallel, Microsys developed expertise in the field of laser processing of metallic layers. We were able, e.g., to cut 8 μm thick aluminium foil without any thermal damages and to pattern features on PCB that are much smaller than the copper thickness.

Ref:

F. Dupont, S. Stoukatch, P. Laurent, S. Dricot, M. Kraft, "355 nm UV laser patterning and post-processing of FR4 PCB for fine pitch components integration", Optics and Lasers in Engineering 100C (2018) pp. 186-194.

SANE (2016 – 2018)

The objective of SANE was the development of wireless and autonomous microsensors for IoT applications. Building upon the results obtained on a previous ERDF project (REMANOS project), the goal of this project was to increase the Technology Readiness Level of the prototype to realize a marketable product in order to answer to the market need in term of wireless and autonomous sensors for IoT applications.

SWS (2016 – 2021)

The SWS (Secure Weapon System) project aims to increase the safety of weapons by implementing three new functionalities: user recognition, electric firing and energy harvesting. Microsys is in charge of developing the energy harvesting module. The primary objective of this module is to collect enough energy to power the weapon user recognition system developed by project partners. The secondary objective is to increase significantly the quantity of energy collected in order to enable electric firing.

TOPPRINT (2015 – 2017)

TOPPRINT project’s objective is the functionalization of 3D industrial pieces by integration of robust and reliable electronic circuits. Microsys task in the project was to perform the characterization of the printed conductive tracks (electrically and mechanically, initially and after isothermal ageing), to provide guidelines about 3D/flexible electronics design and to design a prototype based on an industrial case (using printed tracks in order to replace cables inside an existing device).

Ref:

S. Stoukatch, F. Dupont, L. Seronveaux, D. Vandormael, M. Kraft, "Additive low temperature 3D printed electronic as enabling technology for IoT application", in Proc. of Electronics Packaging Technology Conference (EPTC), 2017 IEEE 19th, December 6-9, 2017, Singapore, p.6.

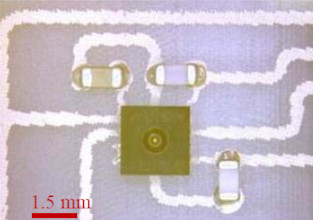

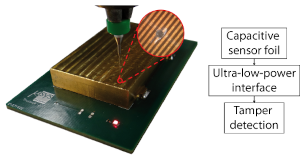

TRUSTEYE (2018 – 2021)

TRUSTEYE project's objective is to develop a miniaturized and low-power secure camera module, with application to dashcam, bodycam, drone camera etc. While project partners are developing image compression algorithms and cryptography, Microsys is in charge of hardware development. First, a miniature module integrating the FPGA and all additional functionalities (such as GPS receiver) was designed and implemented. Second, we developed a hardware anti-tampering system, complementing cryptographic techniques in order to protect data from unauthorized access and/or from data falsification.

Ref:

F. Dupont, P. Laurent, F. Montfort, H. Pierre, L. Jeanne, S. Stoukatch, S. Dricot, J.M. Redouté, "A Miniaturized and Ultra-Low-Power Tamper Detection Sensor for Portable Applications", IEEE Sensors Journal, vol. 22, no. 5, pp. 4524-4533, 1 March, 2022, doi: 10.1109/JSEN.2022.3143656.

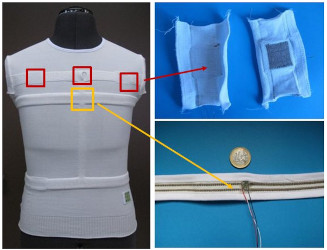

WEARIT4HEALTH (2016 – 2020)

The objective of WEARIT4HEALTH is the creation of a wearable multi sensor monitoring system that is comfortable for the hospitalized patients and compatible with the IT infrastructure of the different hospitals of the Euregio Meuse Rhin.

The monitoring device record medical data into the patient’s EMR, display the measurement in real time on ward’s screens and analyze it in order to help the medical team to take the most adequate decision for the patient. It is also able to inform of risk situation via alarms. Microsys was the scientific lead partner of the project and was leading the development of the wearable monitoring device.

Ref: